Introducing the Solaris hybrid bus

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 27 September 2006 | Ms. Agnieszka Spizewska and Mr. Mateusz Figaszewski, PR Managers, Solaris Bus & Coach | No comments yet

Following the world-wide trend of searching for alternative sources of energy, Solaris Bus & Coach has added a new vehicle to its product range: the hybrid-drive Solaris Urbino. This innovative drive solution helps to significantly reduce fuel consumption and exhaust emissions.

The premiere of the hybrid is scheduled for September of this year at the Hanover IAA bus and coach show. The presentation of this prototype tops a month-long effort by our engineering bureau to present it in time. It goes without saying that developing a new product in such a short time would not have been possible without the support of our experienced partners, the companies Allison and Cummins.

Following the world-wide trend of searching for alternative sources of energy, Solaris Bus & Coach has added a new vehicle to its product range: the hybrid-drive Solaris Urbino. This innovative drive solution helps to significantly reduce fuel consumption and exhaust emissions. The premiere of the hybrid is scheduled for September of this year at the Hanover IAA bus and coach show. The presentation of this prototype tops a month-long effort by our engineering bureau to present it in time. It goes without saying that developing a new product in such a short time would not have been possible without the support of our experienced partners, the companies Allison and Cummins.

Following the world-wide trend of searching for alternative sources of energy, Solaris Bus & Coach has added a new vehicle to its product range: the hybrid-drive Solaris Urbino. This innovative drive solution helps to significantly reduce fuel consumption and exhaust emissions.

The premiere of the hybrid is scheduled for September of this year at the Hanover IAA bus and coach show. The presentation of this prototype tops a month-long effort by our engineering bureau to present it in time. It goes without saying that developing a new product in such a short time would not have been possible without the support of our experienced partners, the companies Allison and Cummins.

The prototype of the hybrid drive Urbino 18 is based on the classic stainless steel skeleton that is used for the whole range of Urbino low floor city buses. It also features a Cummins ISLe4 Diesel engine with 340hp, which has a capacity of 8.9 litres and a maximum torque of 1,500Nm at 1,200rpm.

The second drive element, and the main component of the hybrid bus, is the EP DRIVE system by Allison. Together the Cummins engine and the Allison system form the hybrid drive, which distinguishes itself from other systems through its parallel and series connection properties.

The hybrid drive has been placed at the front part of the bus, immediately behind the fender shield. Due to this it has been possible to obtain 50+1 seats in the bus, 14 of which are accessible directly from the low floor section. The hybrid drive Solaris Urbino 18 prototype can carry a total of 131 passengers, although this figure can be optionally altered to meet customer requirements.

The drive system has been placed in the front part of the bus, behind the first left-hand fender shield. The drive train is diverted to the second (center) axle.

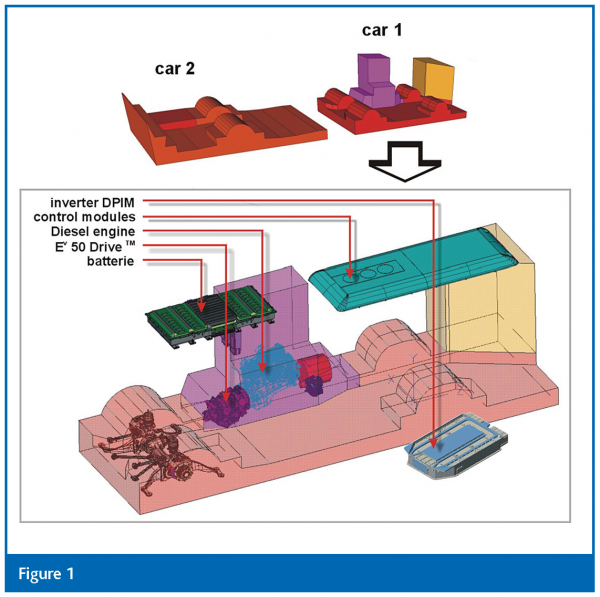

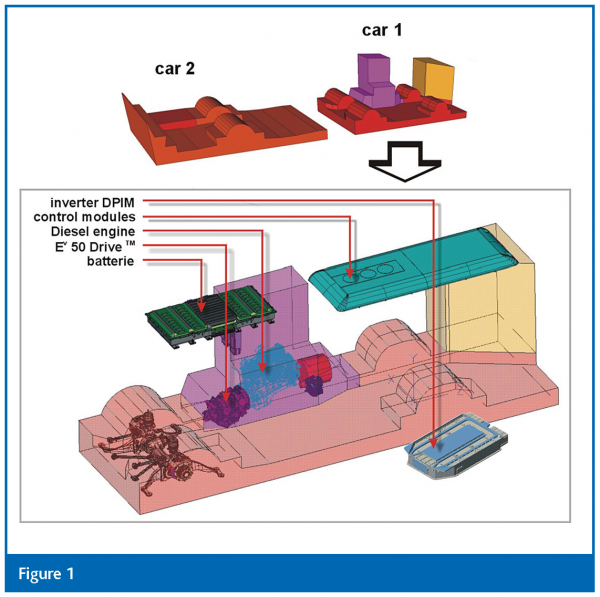

The hybrid drive is completed with roof-mounted batteries and an inverter. Figure 1 gives a schematic illustration of the hybrid drive in the Solaris Urbino 18 prototype.

THE EV DRIVE

THE EV DRIVE is the central element of the hybrid drive, in which a ‘blending’ or combination of the torques of both engines takes place. It consists of two electric engines, two synchronous couplings, and three planetary transmissions. Optically, the EV module resembles a traditional gear box, and weighs 464 kilograms.

THE BATTERY

The energy reconditioned during the slowing-down process is converted accordingly and stored in special roof-mounted batteries. Thus, the batteries utilised by the hybrid drive do not need to be recharged through an outside source of energy.

The lifetime expectancy of the nickel-hydride batteries (NiMH), weighing 410 kilograms, amounts to about six years, depending on the kind of use of the bus.

THE DUAL MODULE (DPIM)

The dual power inverter module (DPIM) is an important electric component of the Allison system. The DPIM consists of two converter modules AC/DC – DC/AC, with a total weight of 91 kilograms. The temperature of the module is kept constant by an oil radiator.

To sum up, the dual mode drive involves the use of the electric engines in order to assist the standard diesel drive, at its optimum load. Through a separate control unit, which co-ordinates the activity of the two drive systems, they are ideally synchronized.

THE DIESEL ENGINE

The Cummins ISLe4 engine has been adapted for use in hybrid drive systems and complies with the Euro 4 standard. This unit is economical with regards to fuel consumption. Its main distinguishing features from the standard version are, among others, its electronic programming function, elimination of the starter engine and an adapter kit.

THE CONTROL UNIT

The system is completed by two control units, mounted onto printed circuit boards. The 1,000/2,000-type units made by Allison weigh only 2.3 kilograms. The first unit is responsible for checking and controlling the hybrid drive, while the second unit co-ordinates the co-operation with the other vehicle modules.

The hybrid bus does not force any radical changes on the driver with regards to the technical aspects of the bus vehicle control. A control unit called drive, neutral, reverse (DNR) has been introduced to operate the hybrid drive. The traditional brake is used only rarely in the hybrid vehicle, as releasing the accelerator is sufficient to slow down the bus. The brake intensity is adjusted by the DNR control unit, which also allows basic diagnostics of the drive system.

EXPERIENCE IN USE

Allison has performed a series of tests in Seattle, Washington, US in March this year, during which the parameters of conventional drive buses were compared to those of the hybrid drive buses. The results clearly speak in favour of the hybrid drive.

The test results indicated:

- a lower fuel consumption (by 20% to 43%)

- a reduction of pollutant emissions (by 10% to 39% concerning nitric oxides)

- a reduction of solid particles in the exhaust fumes (by 51% to 97%).

We think that the majority of bus operators will be particularly interested in the reduction in fuel consumption of the new hybrid bus. Solaris Bus & Coach is also planning to conduct its own studies of hybrid buses in comparison to traditionally powered vehicles, in addition to the tests conducted in the US. These will be the first comparative tests of their kind in Europe.

Further features of the hybrid drive Solaris Urbino 18 include:

- front suspension / steering ZF RL 75 EC

- drive axle AV 132 80/5

- rear axle AVN 132

- central lubrication system KFBS1 with auto diagnosis

- articulation joint Hemscheidt, puller-type.